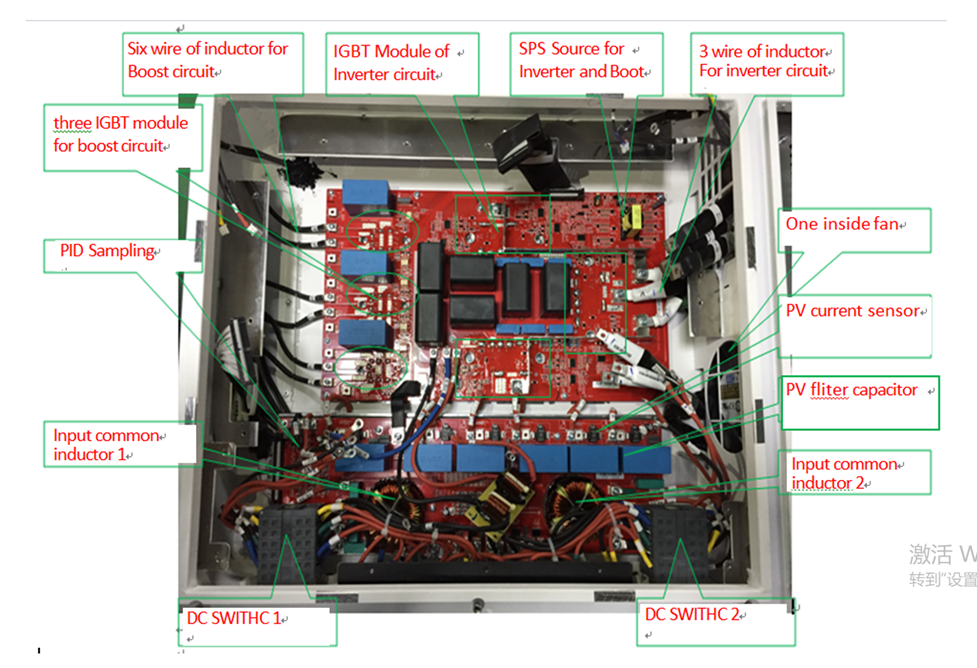

MAX 50K-80K TL3 introduction

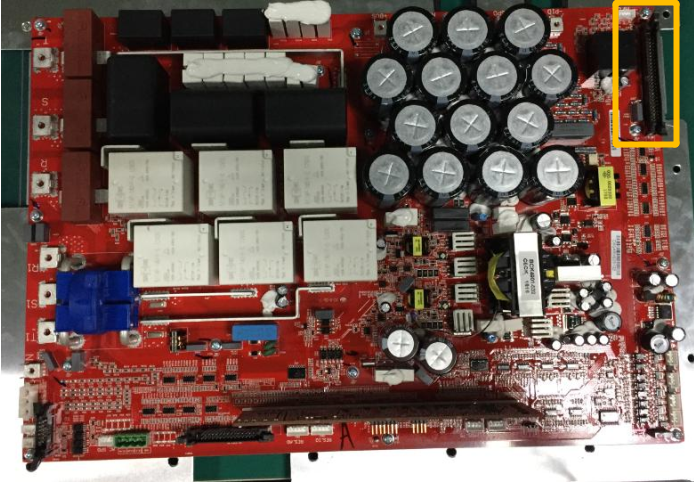

1. Product appearance

MAX LV model and MAX MV model have same boards

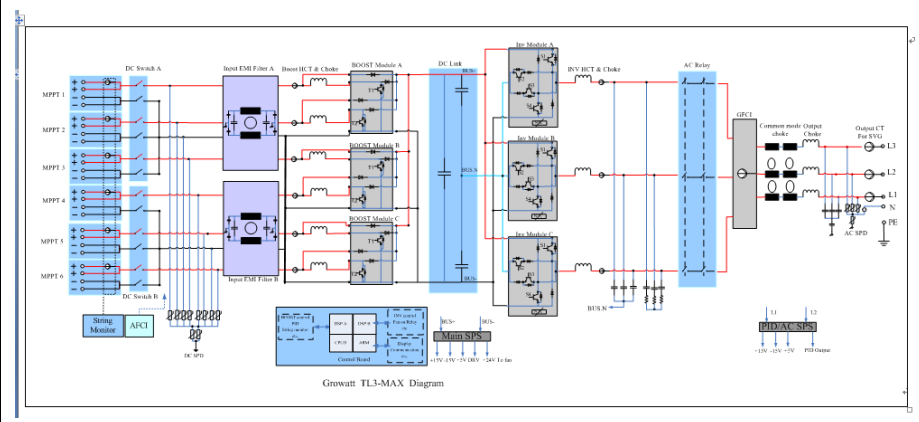

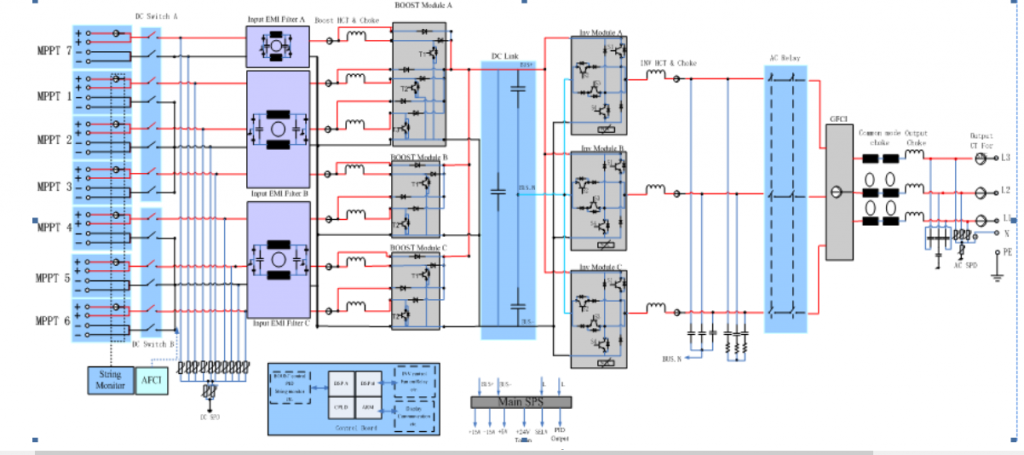

2. System Diagram

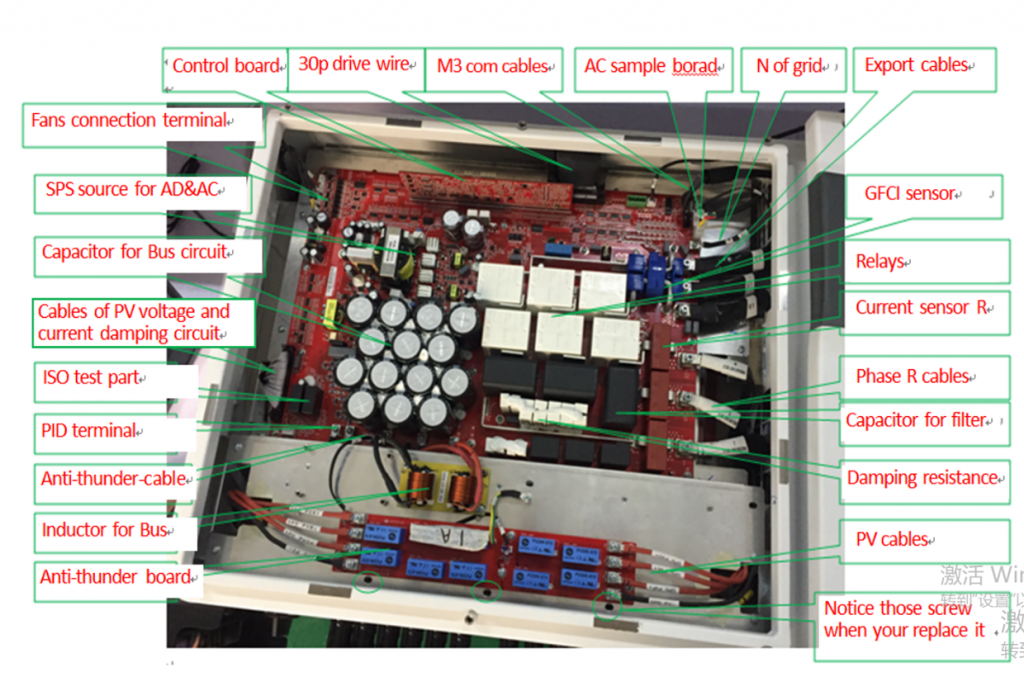

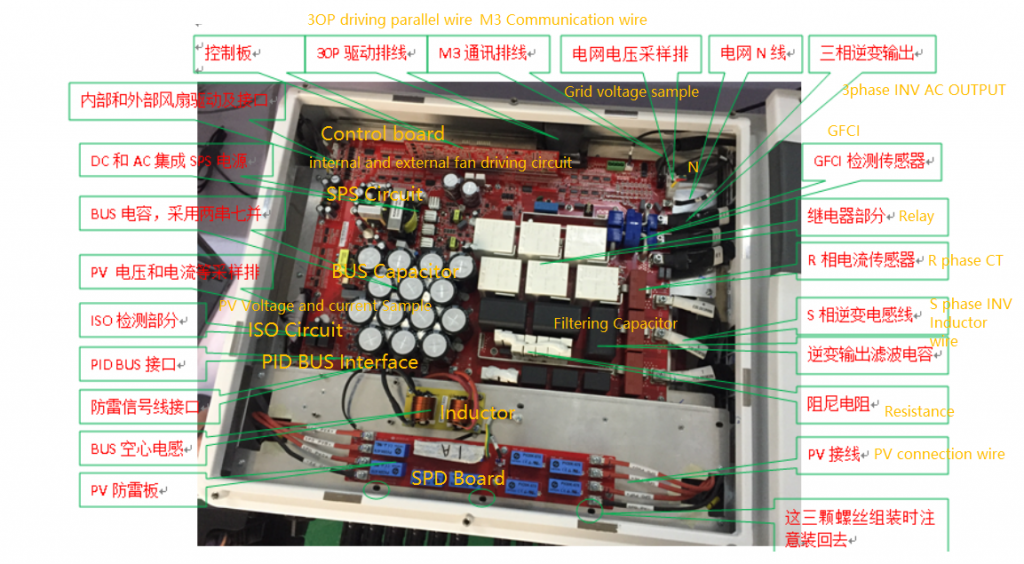

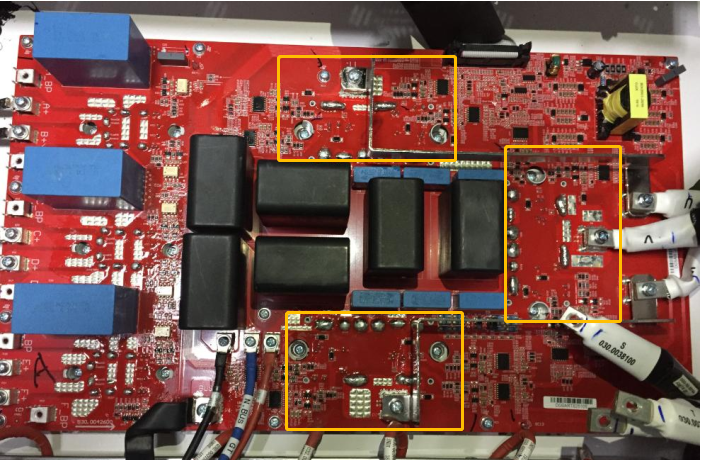

3. Board Introduction

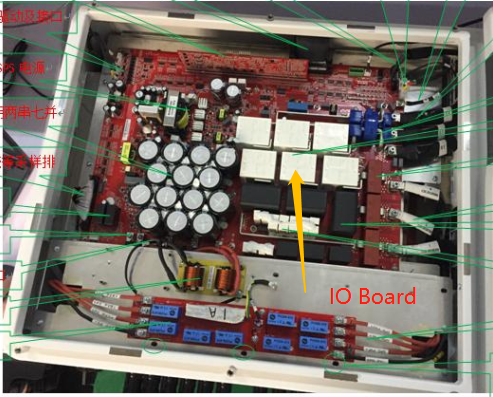

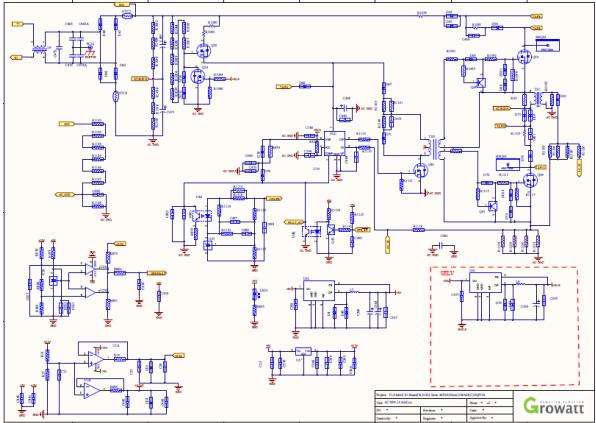

IO Board

SPD Board

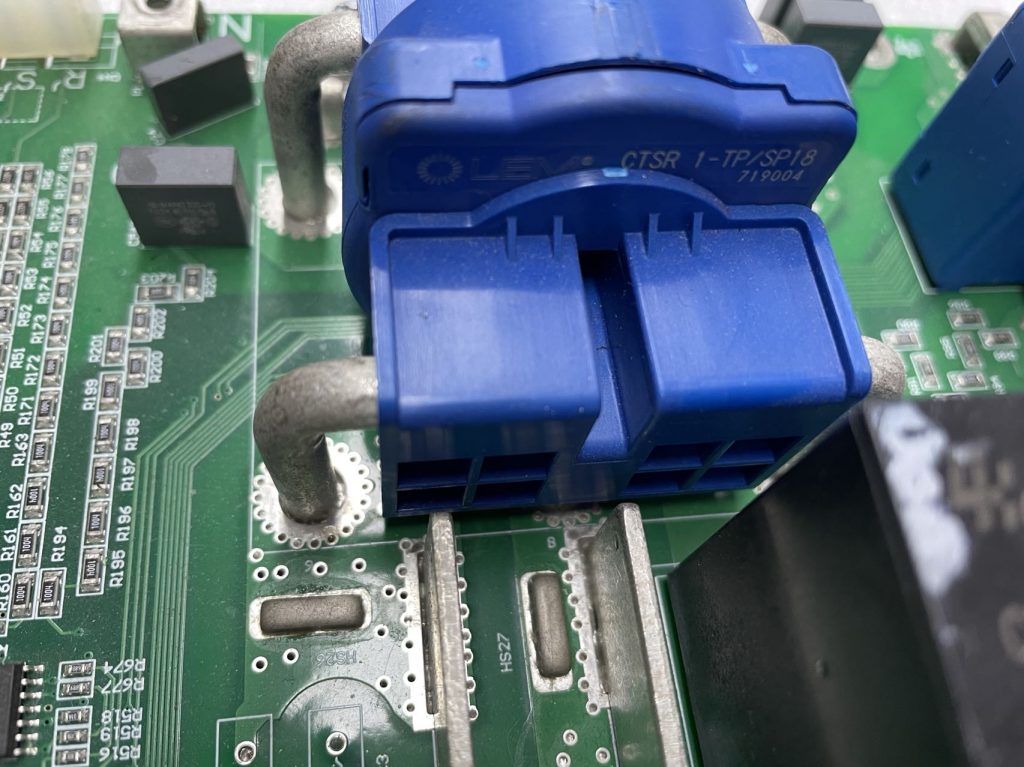

It is used to prevent lighting strike

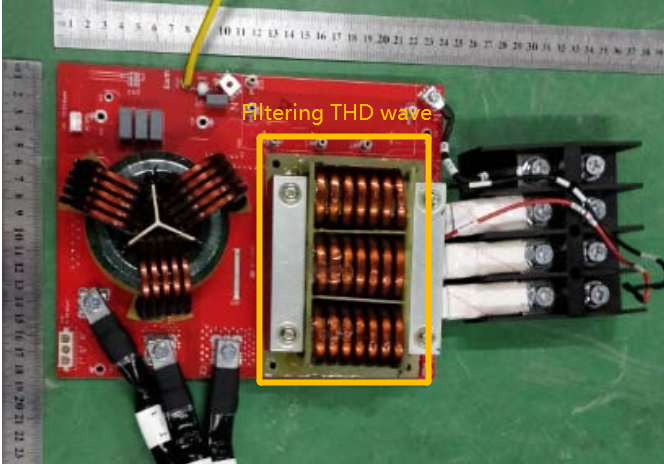

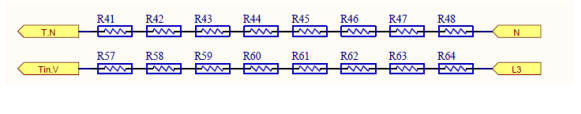

Inductor

It is used in BUS circuit and it is function is filtering wave

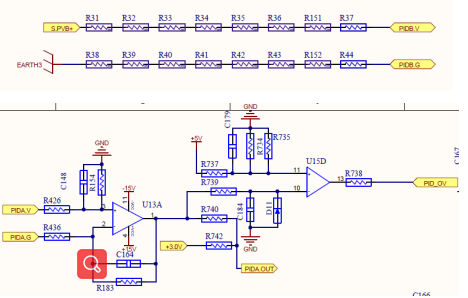

PID BUS Interface

PID means ” PotenTIal Induced DegradaTIon “, The direct harm of PID is that a large amount of charge accumulates on the surface of the cell, which deteriorates the passivation effect of the cell surface, resulting in a decrease in the fill factor, open-circuit voltage, and short-circuit current of the cell, and the power attenuation of the battery module.

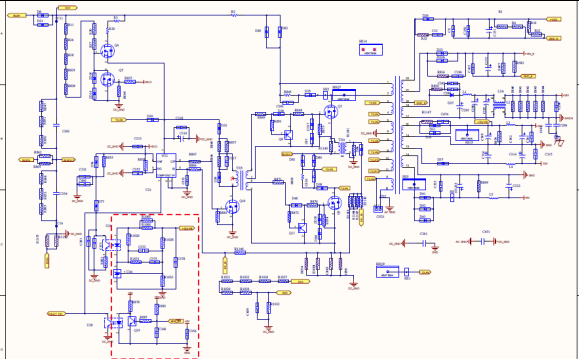

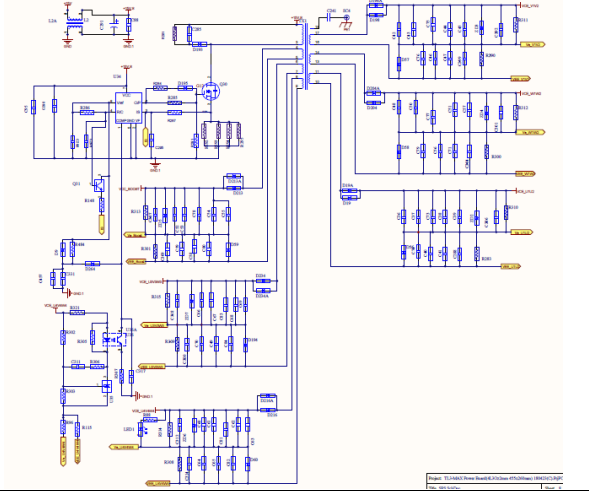

SPS circuit

main SPS circuit

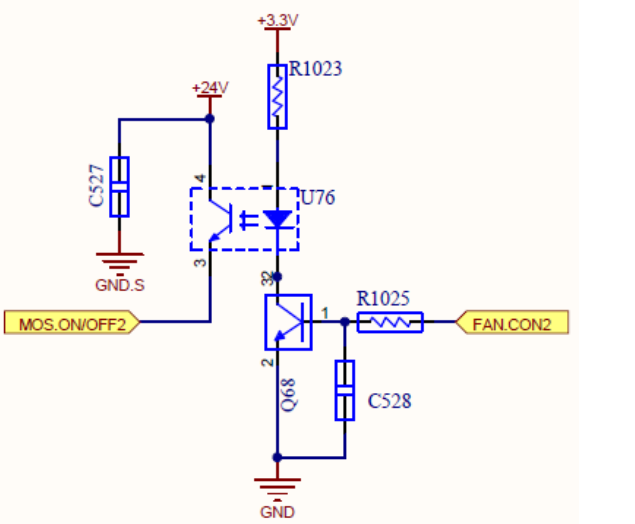

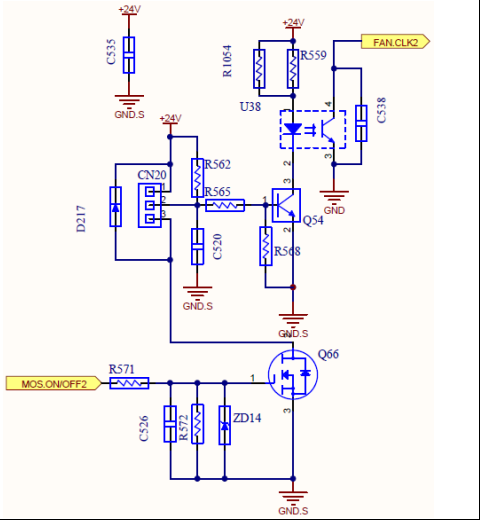

Internal and external fan driving circuit

3OP driving parallel wire

It is used to drive Boost and DC-AC circuit , SPS circuit on mainboard

Resistance

It has been cancelled in new MAX series.

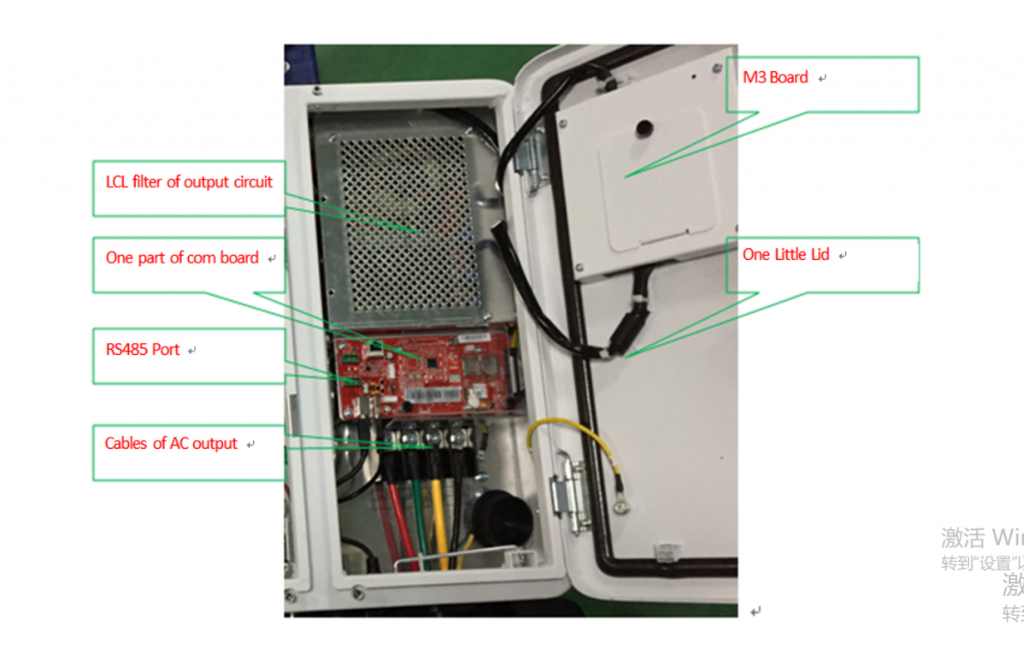

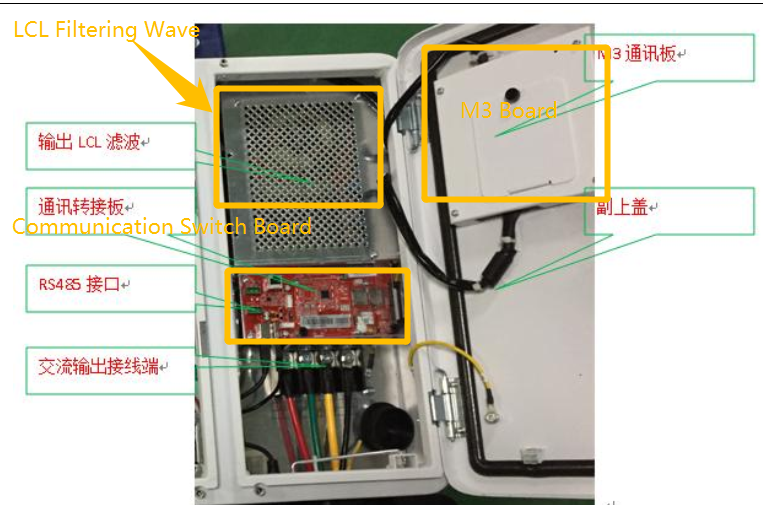

Left Cover of Max Inverter

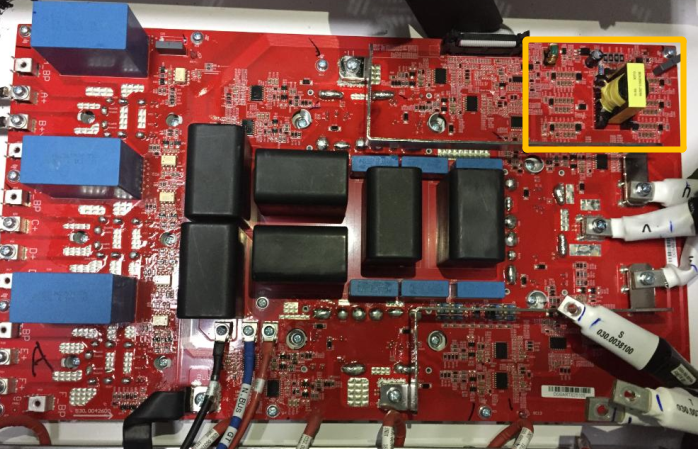

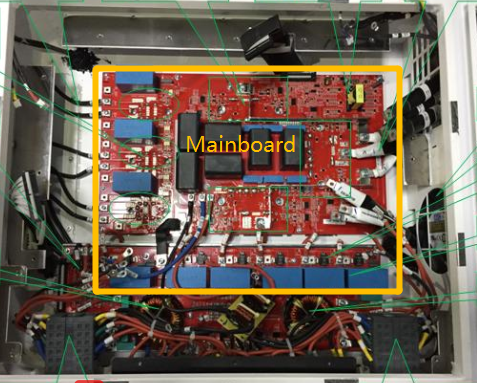

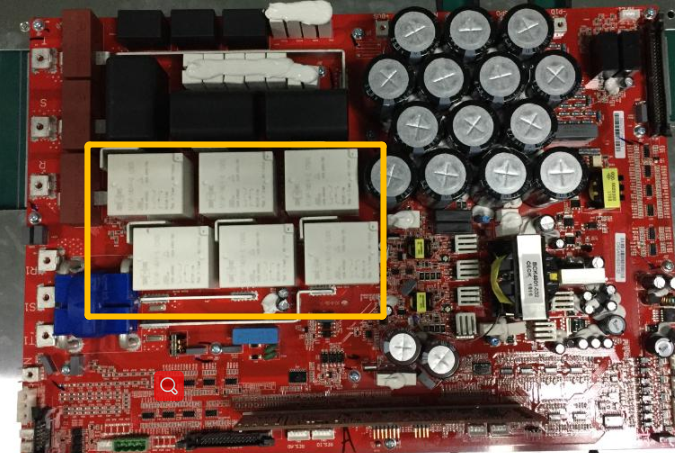

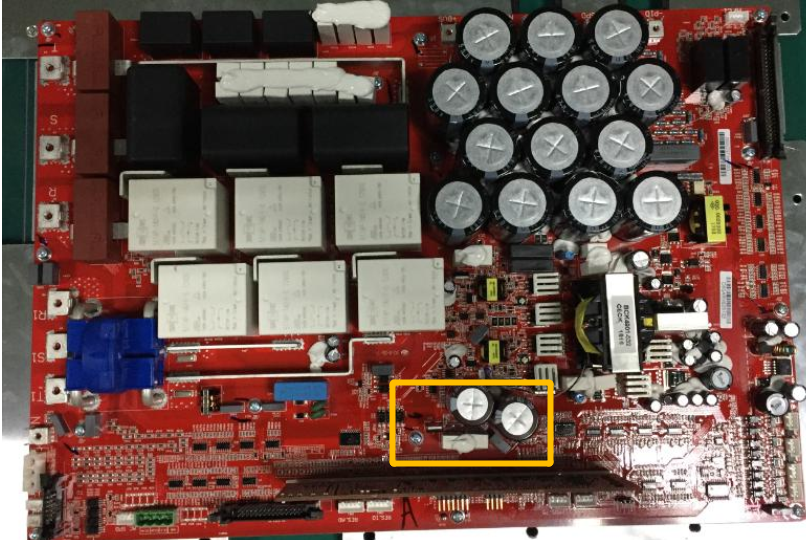

Main board

PV INPUT board

SPD board

Right Cover of Max Inverter

AC Filtering board

AC SPD board

M3 board

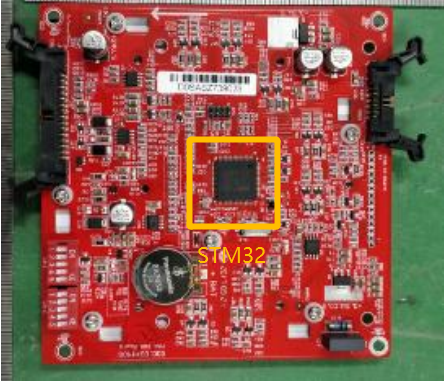

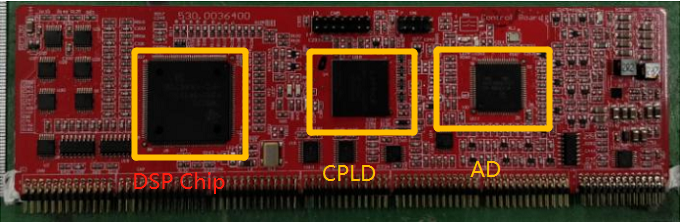

Control board

DSP Chip called 75 chip , Mainly deal with AC output Sampling data

AD chip called 67 chip, mainly deal with PV Sampling data

CPLD is used to produce wave and drive related circuit.

Communication Switch Board

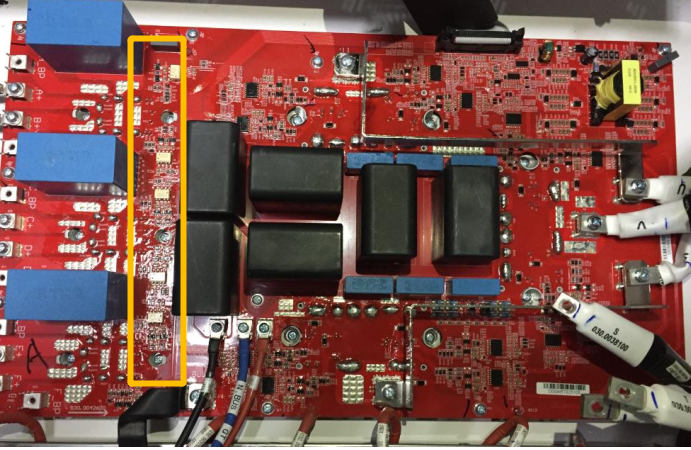

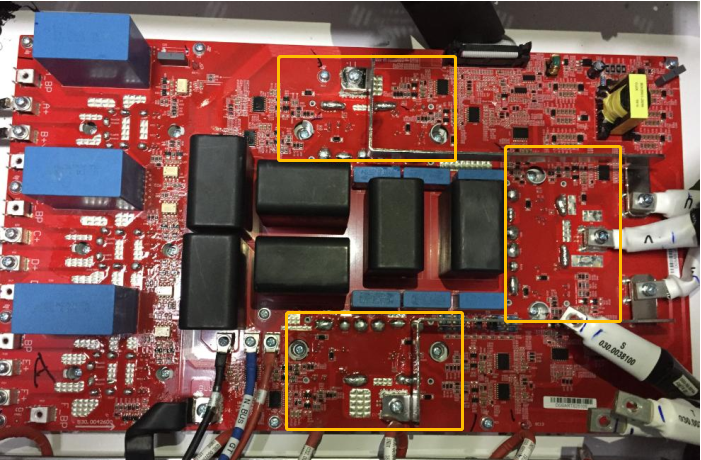

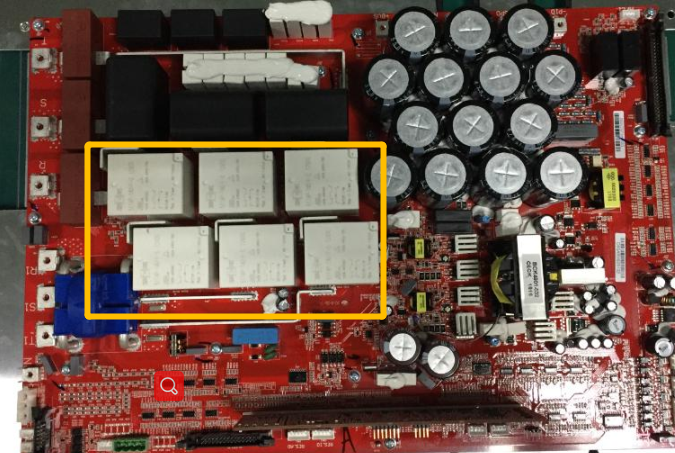

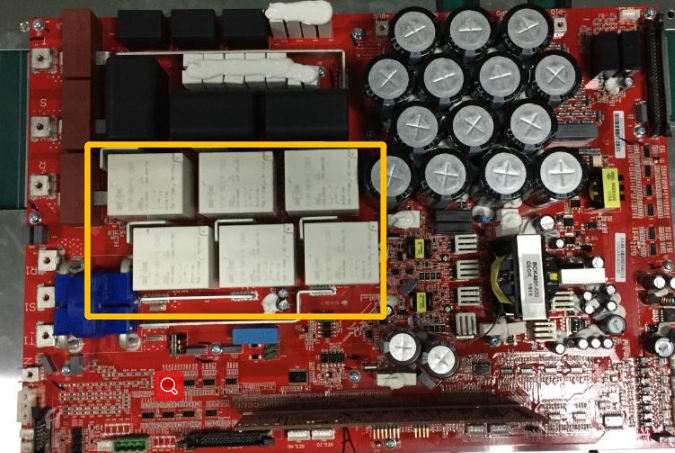

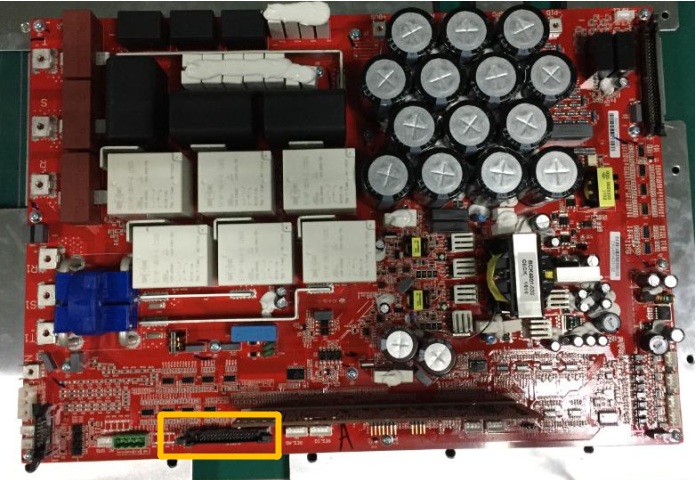

4. Board Position

5. Electrical Diagram Introdcution

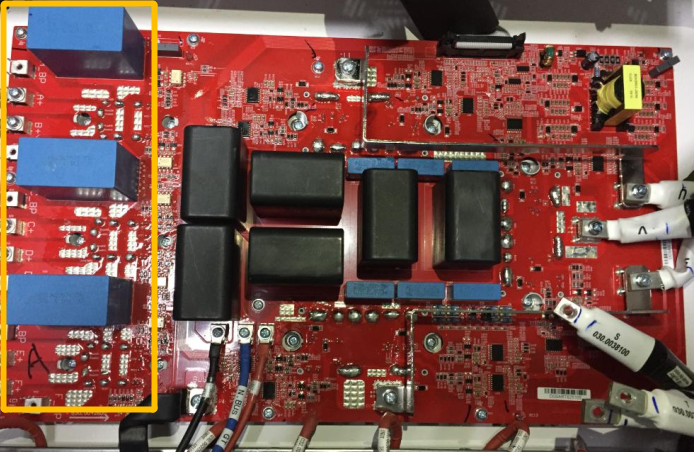

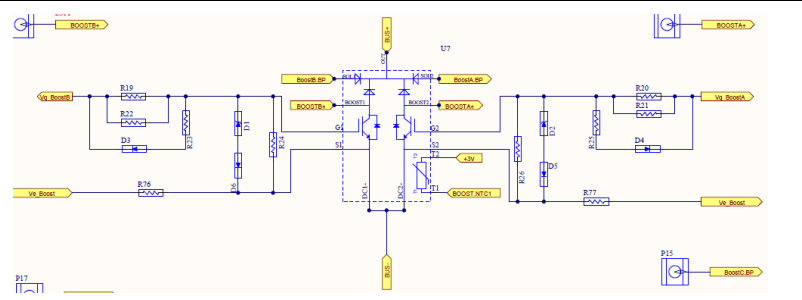

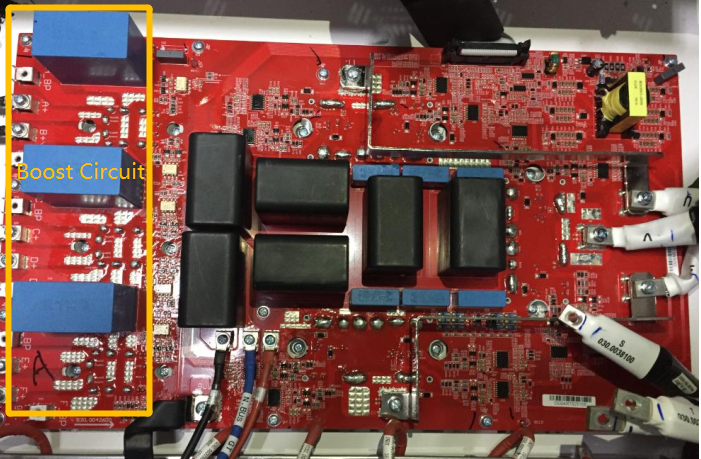

Boost Circuit on mainboard

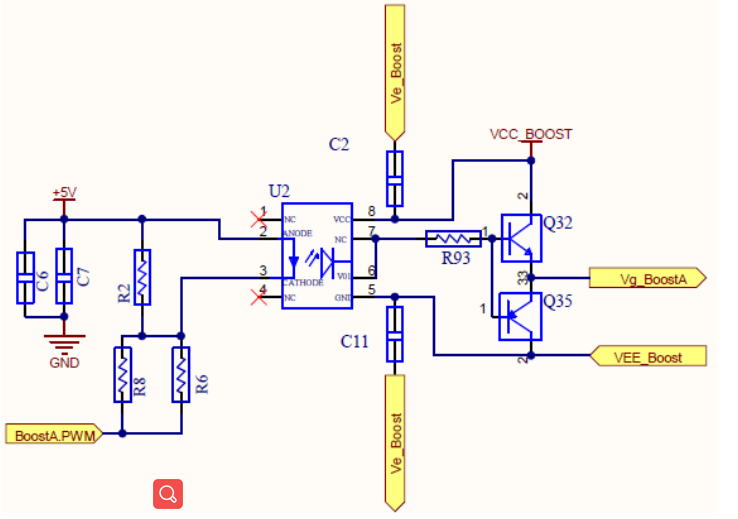

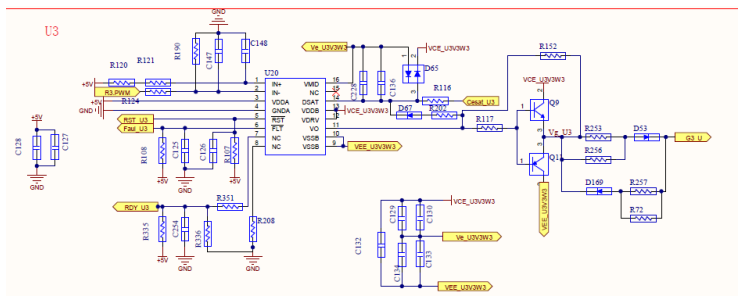

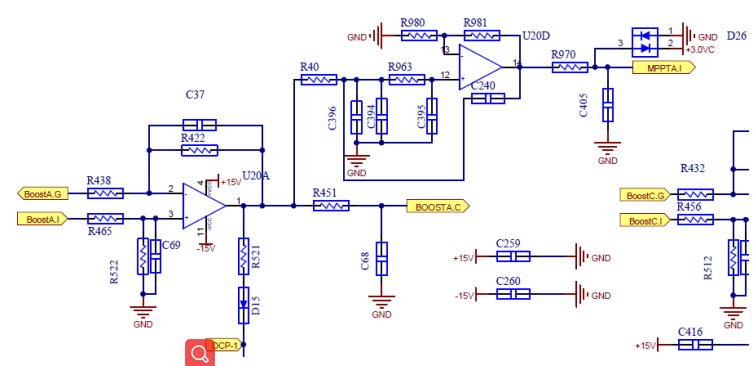

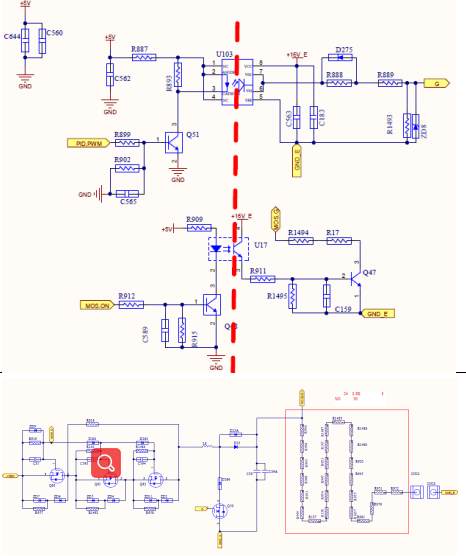

Driving circuit of Boost Circuit

BOOST. PWM1 is introduced into the main board from the control board through the 30PIN cable of the IO board, and outputs BoostA.PWM after passing through the optocoupler TLP352

As the driver of the BoostA. The other five are the same

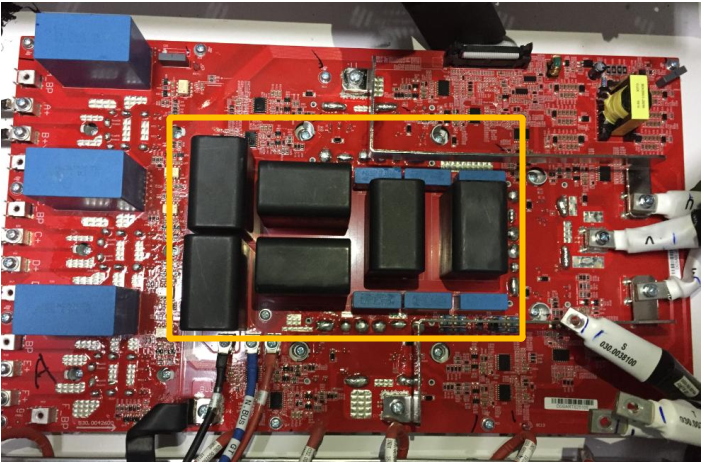

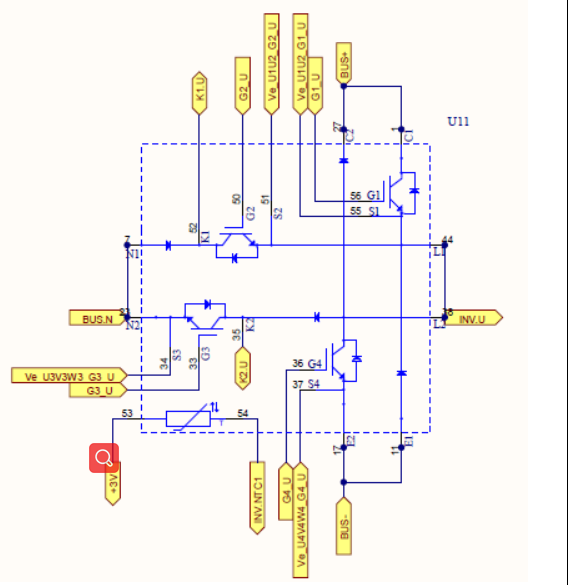

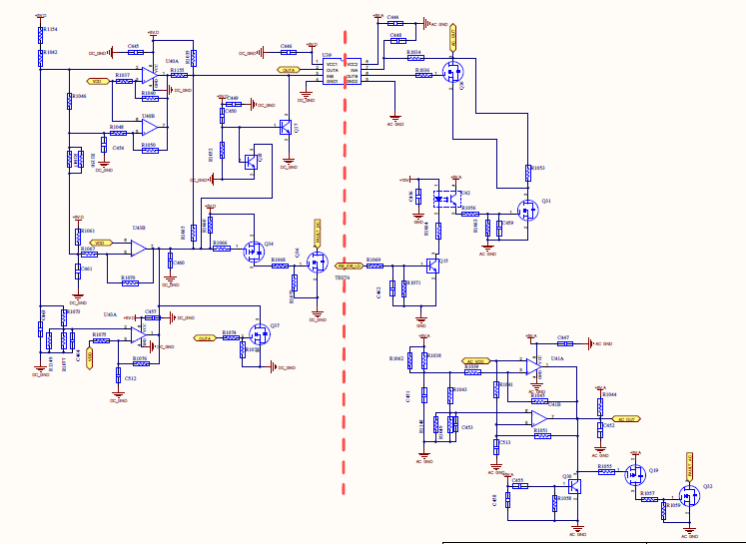

INV Driving Circuit

There are 12 routes in total on Inverter drive circuit, PWM through 8286 driver chip output Give to push-pull and then to Vge of IGBT

Full Bridge Circuit

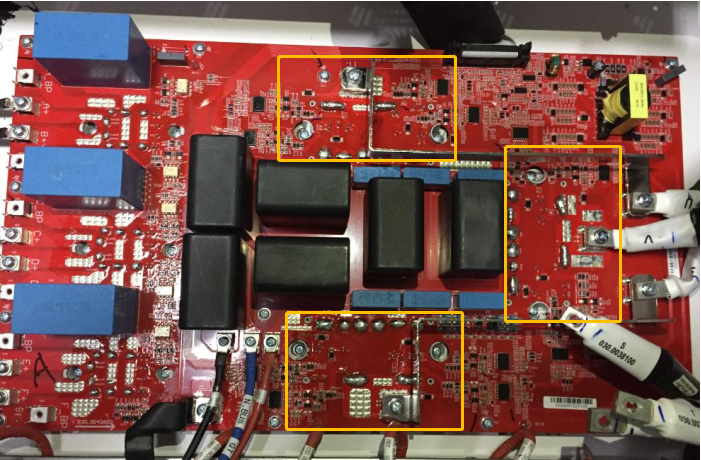

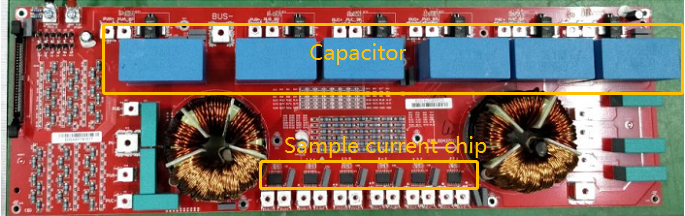

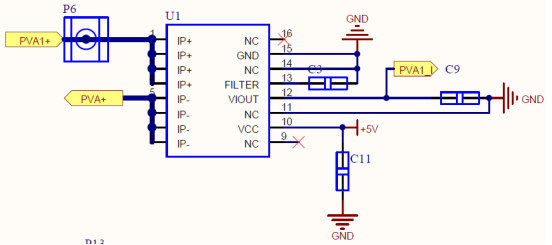

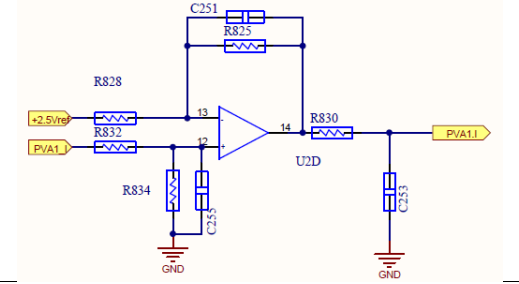

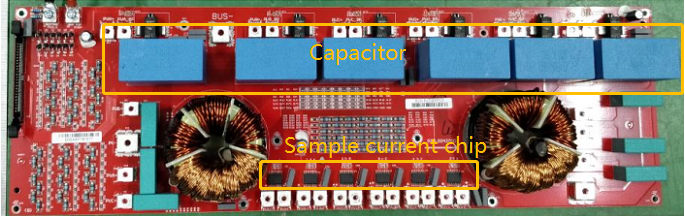

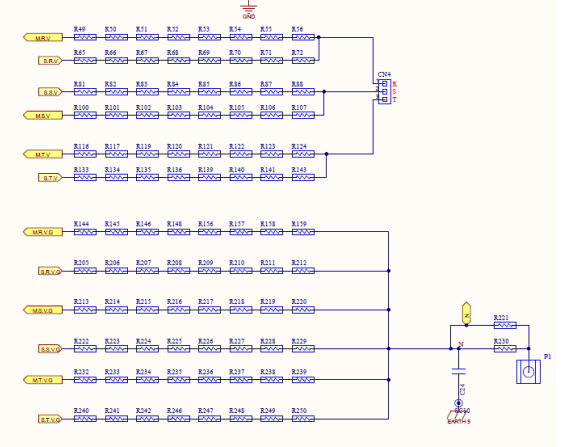

PV String Current Sampling Circuit

String current sampling circuit, the string current passes through the string chip and outputs the sampling voltage, and output of the sampling circuit to the operational amplifier

After scaling, it is given to the AD port of the control board to convert the current.

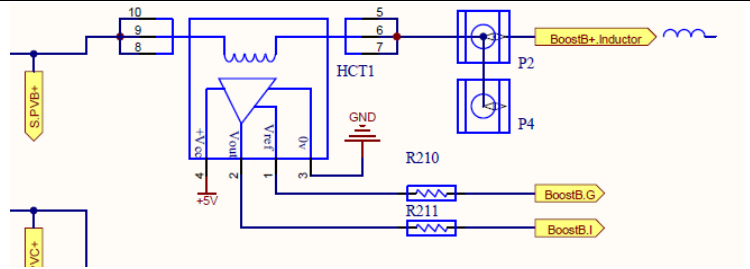

Boost Current Sampling Circuit

PV current through HCT (Current Sensing device) sampling, HCT voltage type, straightly Connect output sampling voltage. There are 6 routes in total

The PV current (BOOST inductor current) is sampled through the HCT. When a current flows through the HCT, the HCT itself outputs a sample signal. The sample voltage increases linearly (that is, the greater the current flowing, the greater the output voltage),

HCT output sampling After the voltage is transported After zooming to the control panel AD port to read Get real-time PV curren

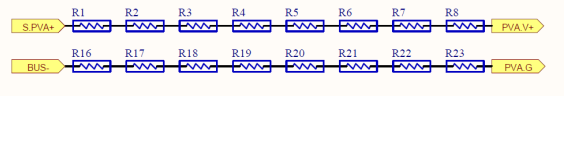

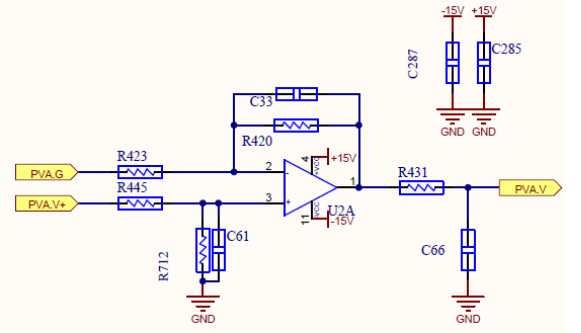

PV voltage Sampling Circuit

PVA road is the reference test, other five

the same way. Sampling resistor at PVinput

Board

stream to PVA as a reference, The other five Same.op on IO board.

The PV voltage is divided by the resistor and sent to the op amp for scaling, and then sent to the control AD port for operation, so as to sample the PV Voltage.

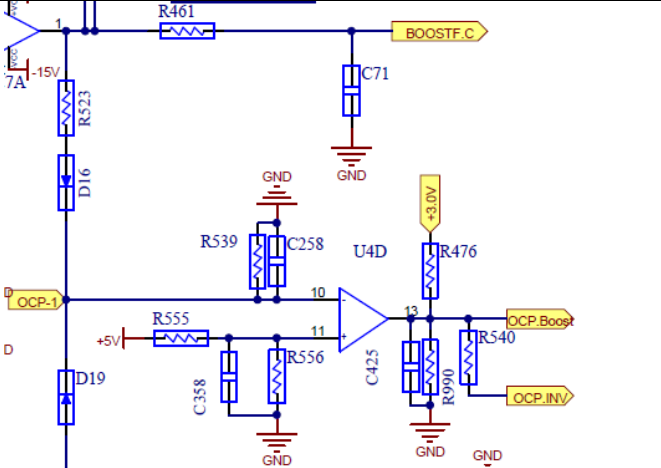

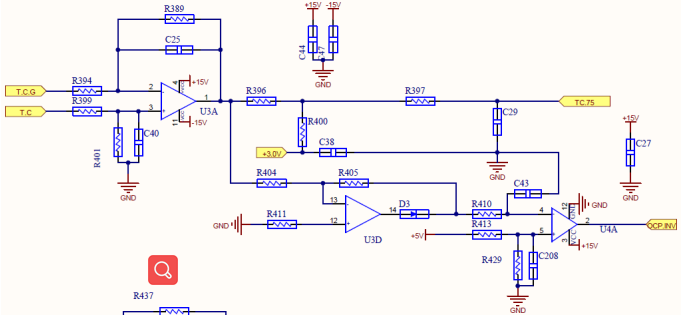

BOOST OCP Protection Circuit

BOOST OCP Protection Circuit output voltage with an electron and diode via sampling current Op amp

Compare negative output of the comparator and positive voltage

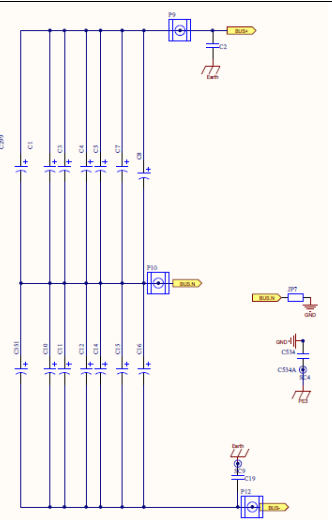

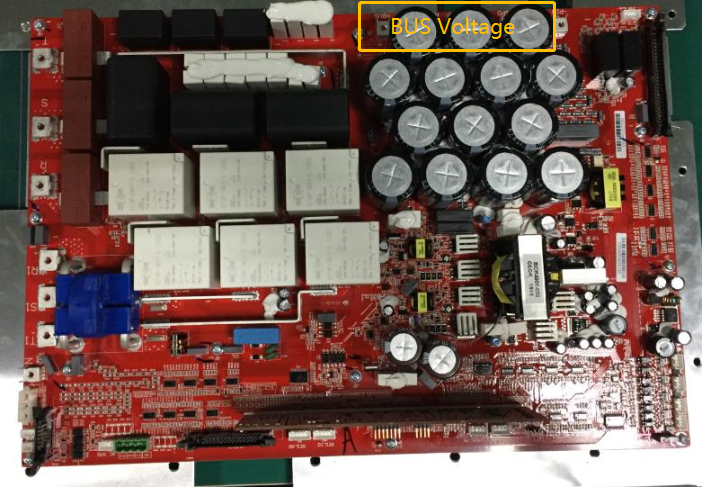

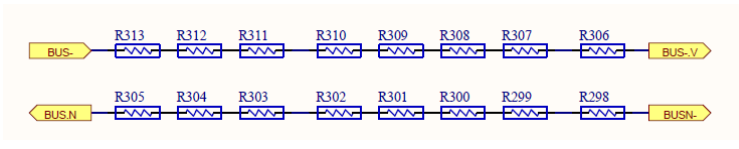

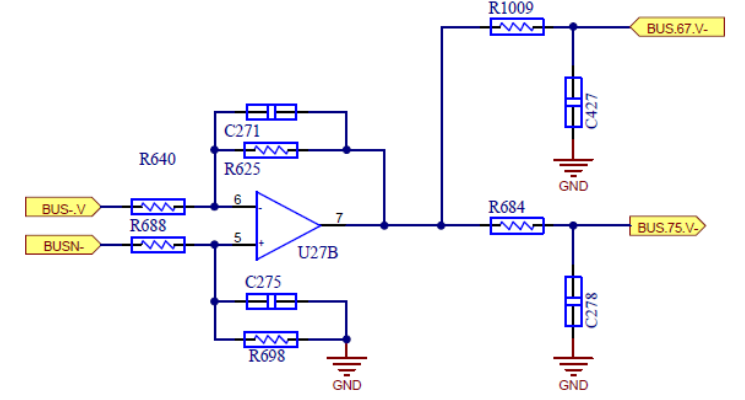

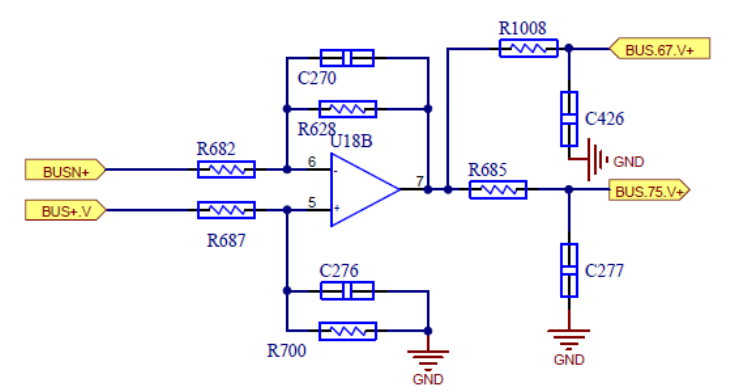

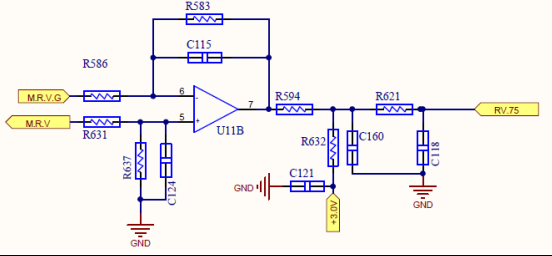

BUS Voltage Sampling Circuit

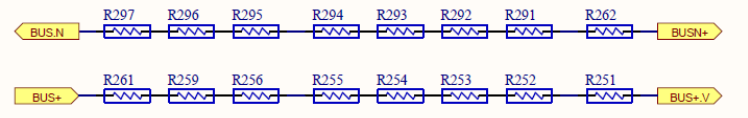

Negative BUS voltage Sampling Resistance

Negative BUS voltage Sampling op amp The output is divided into Second, give to 075 and 067 control chip

Positive BUS voltage Sampling Resistance

The total BUS voltage is summed by the positive and negative BUS voltages, and the positive and negative BUS voltages are sampled respectively, and then given by the op amp scaling.

The AD port of the control chip performs sampling and calculation to obtain the real-time voltage, and the output of the op amp is divided into two parts, which are respectively given to two different chips for sampling.

AC Current Sampling and OCP Protection Circuit

HCT Current Sensing sampler

voltage to the op amp after zooming

is given to control

Board AD port.

OCP is made by

After the sample is taken out separately

given to the comparator

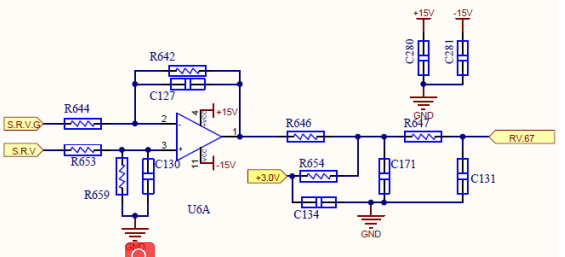

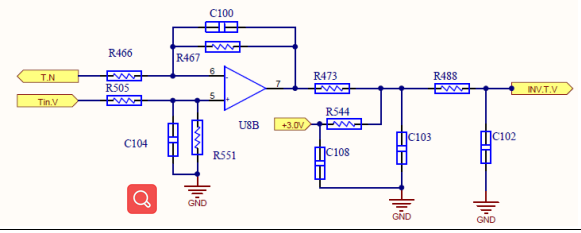

AC Voltage Detecting Circuit

Voltage sampling operation

output to

075 Chip

Voltage sampling operation

output to

067 Chip

The grid voltage is given to the op amp after being divided by the resistor, and then given to the control chip after scaling, and the two chips are sampled separately

The inverter voltage is divided by the resistor and given to the op amp, and after scaling, it is given to the control board for sampling operation.

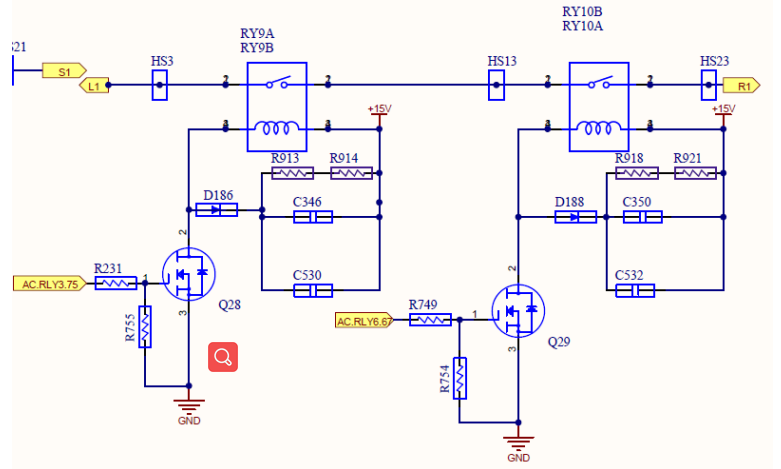

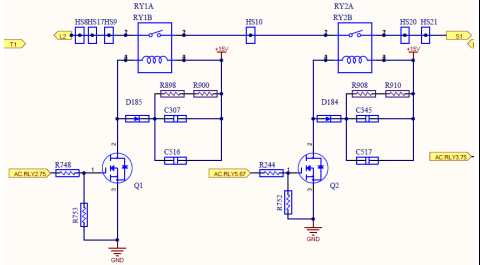

R phase Relay Circuit

S phase Relay Circuit

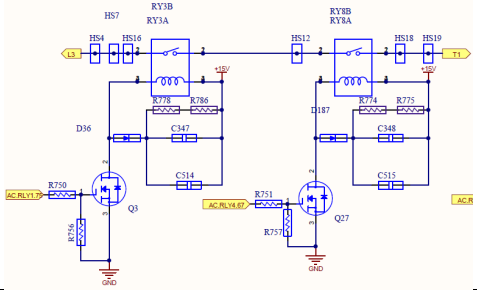

T phase Relay Circuit

When it is about to be connected to the grid, the relay detection is carried out, and by switching the relay, and control INV Circuit to form wave., so that the inverter output and the grid Voltage at the same frequency and the same volt value, compare the voltage difference between the inverter side and the grid side to judge whether the relay can work normally

Detection logic:

1. Before the inverter produces the wave (before the relay driver works), detect the voltage across the inverter and the grid, if there is a large voltage difference 80V indicates that the first step has passed the test;

2. After the inverter produces the wave, firstly close the inverter relay to detect the voltage across the inverter and the grid.

If there is no voltage difference between the two ends, it means the relay on the grid side is stuck (or on the inverter side).

3. After the inverter produces the wave, firstly disconnect the inverter side relay, and then close the grid side relay to detect the power at both ends of the inverter and the grid. If there is no voltage difference between the two ends, it means that the inverter relay is stuck (the above inverter side is excluded at this time), otherwise there is a voltage difference and is greater than 80V

It means that there is no sticking;

4. At this time, close the relay on the inverter side again, and check the voltage across the inverter and the grid. If there is no voltage difference. It means that the detection is normal, and it is connected to the grid. Otherwise, there is a voltage difference and it is greater than 80V, which means that the relay cannot be closed.

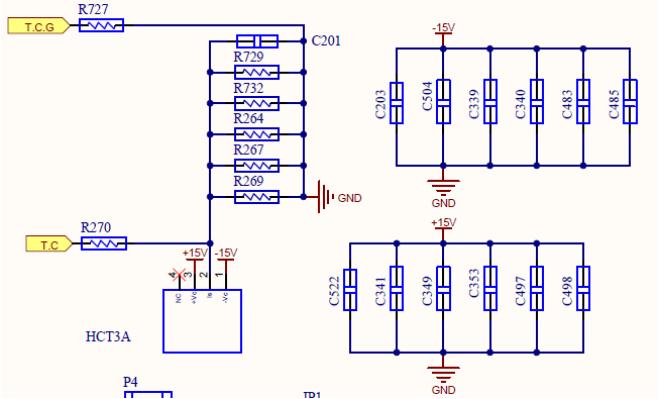

Main SPS Circuit

Auxiliary power SPS adopts integrated DC SPS and AC SPS, that is, DC SPS and AC SPS share a transformer,

The secondary side outputs are together, and the DC SPS takes power from the BUS, adopts an overlapping flyback topology circuit, and uses 2844 for the control driver chip;

The AC SPS takes power from the ST two-phase uncontrolled rectification, and also uses the overlapping flyback topology circuit, and the control driver chip also uses 2844.

The primary side of the transformer is controlled separately

DC SPS or AC SPS operation is performed by voltage judgment through comparator.

Input voltage range: PV =200-1100v, AC= 210v-615V

Output voltage range: +15V, -15v, 8V, 8v convert to 5V( 2567 Buck chip Degarde ),24V (Fans), 24V converted to 5V( 2567 Buck chip Degarde, for communication ), 100V( PID Input Voltage ), 15V(PID Driving Voltage)

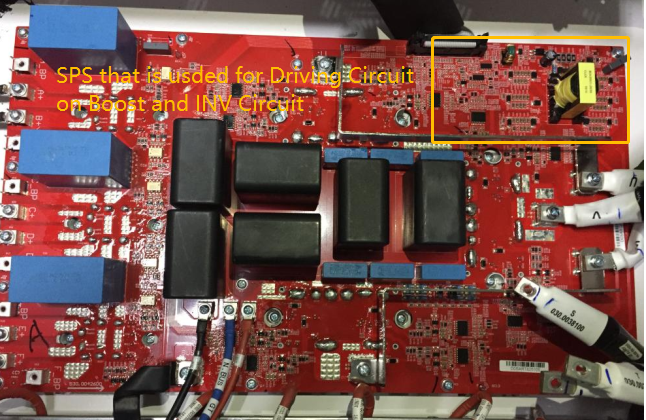

SPS Cirucuit on mainboard ( It is used for Boost and INV Driving Circuit)

The BOOST drive voltage and inverter drive voltage of this model consist of an independent SPS. is a flyback topology, the control

chip is 2843, and there are 6 sets of outputs (the total output voltage of each channel is 22V, and then 15V is clamped by the Zener diode

and -7V. ), input 15V from main SPS output as power supply

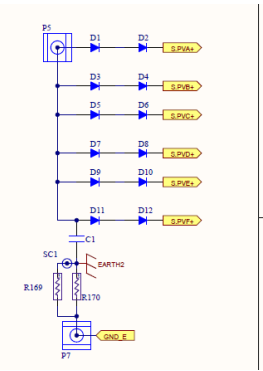

PID Circuit( Potential Induced Degradation )

PID working principle: It is to increase the voltage between PE ( ground) and PV+, and optimize the panel at night. actually

The topology of PID boosting is a BOOST circuit. After the main SPS outputs 100V, the voltage is boosted to the set voltage value.

output, go

through the diode

directly after

PV input

positive electrode

FAN Circuit

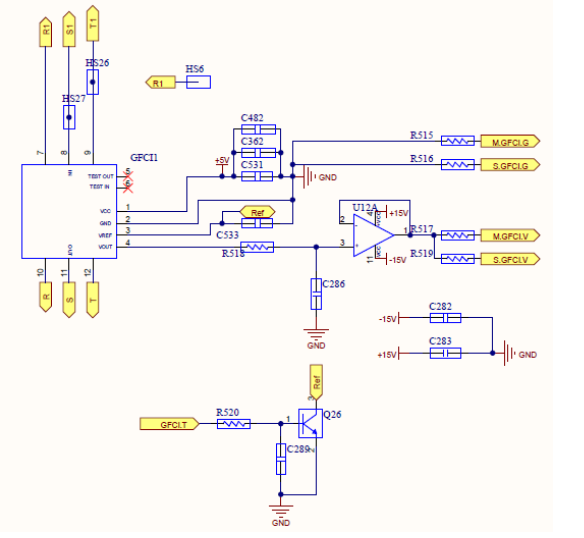

GFCI Circuit (Ground Fault Circuit-Interrupter)

Principle: It is like RCD. When 3 phase in balance, current of Neutral line should be 0

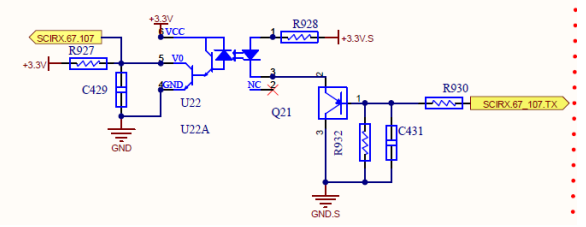

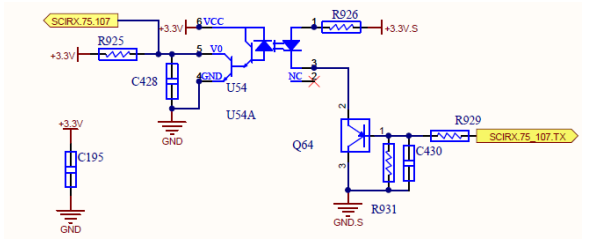

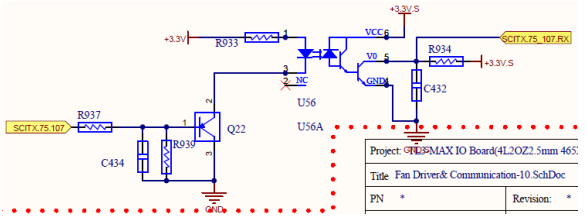

Internal Communication Circuit (Between M3 board and control board)

Between 067 Chip on control board and M3 board

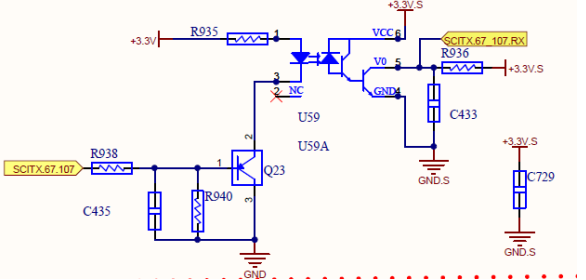

Between 075 Chip on control board and M3 board

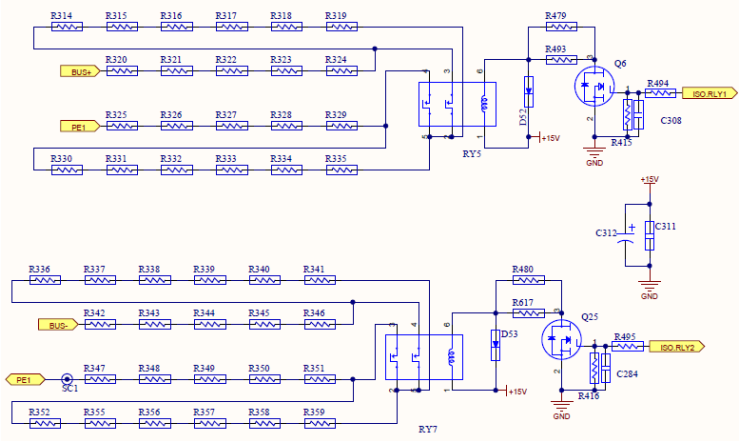

ISO Circuit

The ISO detection circuit samples the voltage at both ends through the opening and closing of two relays, and then calculates the impedance between PV+ and PV- to PE. So as to determine whether it is OK.

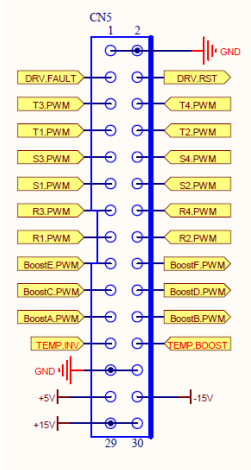

30PIN Drive Row Wire

1,2 GND Control ground

3 DRV.Fault Driving fault alert

4 DRV.RST

5 T3.PWM T phase G3 IGBT Driving

6 T4.PWM T phase G4 IGBT Driving

7 T1.PWM T phase G1 IGBT Driving

8 T2.PWM T phase G2 IGBT Driving

9 S3.PWM S phase G3 IGBT Driving

10 S4.PWM S phase G4 IGBT Driving

11 S1.PWM S phase G1 IGBT Driving

12 S2.PWM S phase G2 IGBT Driving

13 R3.PWM R phase G3 IGBT Driving

14 R4.PWM R phase G4 IGBT Driving

15 R1.PWM R phase G1 IGBT Driving

16 R2.PWM R phase G2 IGBT Driving

17 BoostE.PWM BOOST E Driving

18 BoostF.PWM BOOST F Driving

19 BoostC.PWM BOOST C Driving

20 BoostD.PWM BOOST D Driving

21 BoostA.PWM BOOST D Driving

22 BoostB.PWM BOOST B Driving

23 TEMp.INV INV Temperature detecting

24 TEMp.BOOST BOOST Temperature detecting

25, 26 GND Control ground

27 +5V Main SPS power Supply

28 -15V Main SPS power Supply -15V

29.30 +15V Main SPS power supply +15V

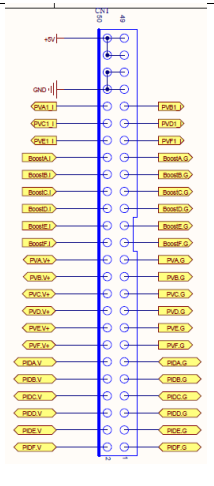

50PIN Drive Row Wire

1、 2 pin:

PIDF.V PIDF.G

PID F Route Voltage Sampling

3、 4 pin:

PIDE.V PIDE.G

PID E Route Voltage Sampling

5、 6 pin:

PIDD.V PIDD.G

PID D Route Voltage Sampling

7、 8 pin:

PID C Route Voltage Sampling

9、10 pin:

PID B Route Voltage Sampling

11、12 pin:

PIDA.V PIDA.G

PID A Route Voltage Sampling

13、14 pin

PVF.V+ PVF.G

PV F Route Voltage Sampling

15、16 pin

PV E Route Voltage Sampling

17、18 pin

PVD.V+ PVD.G

PV D Route Voltage Sampling

19、20 pin

PVC.V+ PVC.G

PV C Route Voltage Sampling

21、22 pin

PVB.V+ PVB.G

PVB Route Voltage Sampling

23、24 pin

PVA.V+ PVA.G

PVA Route Voltage Sampling

25、26 pin

BoostF.I BoostF.G

PV F Route Inductor current Sampling

27、28 pin

BoostE.I BoostE.G

PVE Route inductor current Sampling

29、30 pin

BoostD.I BoostD.G

PV D Route inductor current Sampling

31、32 pin

BoostC.I BoostC.G

PV C Route Inductor Current Sampling

33、34 pin

BoostB.I BoostB.G

PV B Route Inductor Current Sampling

35、36 pin

BoostA.I BoostA.G

PV A Route Inductor Current Sampling

37 pin

PVF1_I

PVF Route String Current Sampling

38 pin

PVE1_I

PV E Route String Current Sampling

39 pin

PVD1_I

PVD String Current Sampling

40 pin

PVC1_I

PV C Route String Current Sampling

41 pin

PVB1_I

PVB Route String Current Sampling

42 pin

PVA1_I

PVA String Current Sampling

43、44、45、46 pin

GND

Control Ground

47、48、49、50 pin

+5V

Main SPS power supply +5V

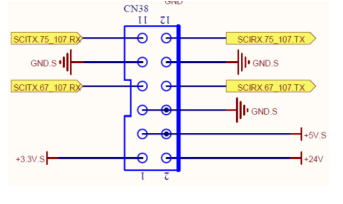

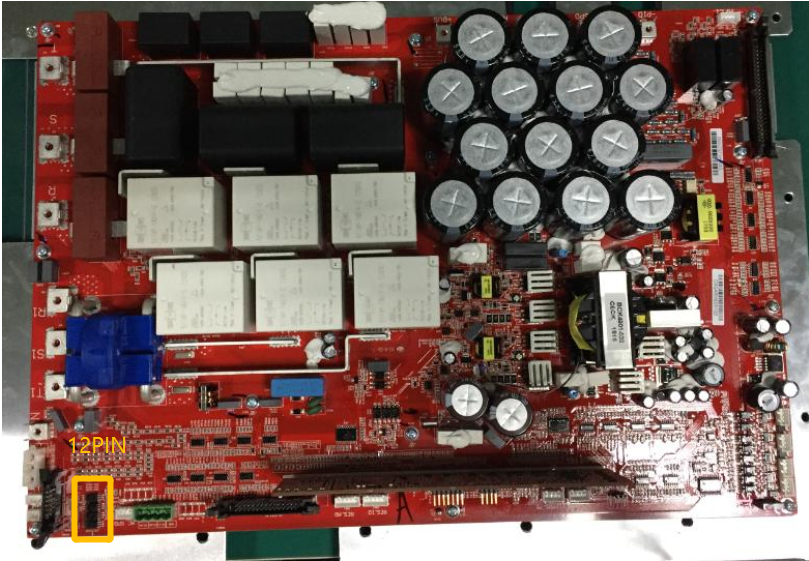

12 PIN Communication Row Wire

1 pin

+3.3V.S

SPS power supply +3.3V.S

2 pin

+24V

SPS power supply 24V

3、 4 pin

+5V.S

SPS power supply +5V.S

5、 6 pin

GND.S

Communication control ground

7 pin

SCITX.67_107.RX

067 sending data

8 pin

SCIRX.67_107.TX

067 receiving data

9 、10 pin

GND.S

Communication control ground

11 pin

SCITX.75_107.RX

075 sending data

12 pin

SCIRX.75_107.TX

075 receiving data

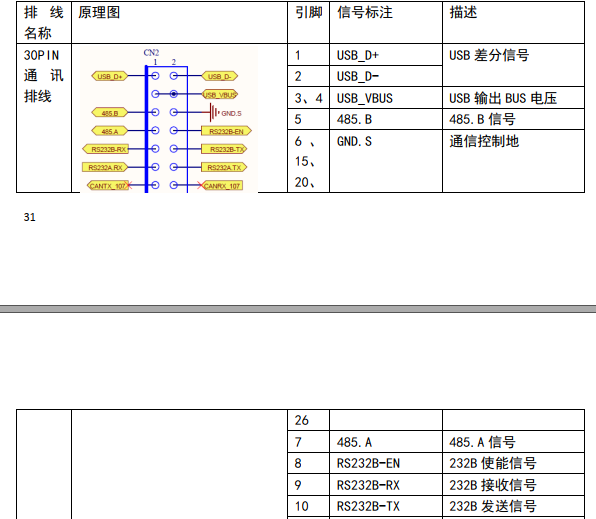

30 pin Communication row wire

1,2 pin

USB D+ USB D-

USB differential signal

3,4 pin

USB_VBUS

USB output BUS voltage

5 pin

485.B

485.B Signal

6, 15, 20,26 pin

GND.S

Communication control ground

7 pin

485.A

485 A signal

8 pin

RS232B-EN

232B Enable signal

9 pin

RS232B-RX

232B Receiving signal

10 pin

RS232B-TX

232B Sending signal

11 pin

RS232.RX

232A Receiving data

12 pin

RS232A.TX

232A Sending data

13 pin

CANTX_107

CAN Sending signal

14 pin

CANRX_107

CAN Receiving data

16 pin

USB.ID

17、18 pin

+5V.S_OUT

Chip output 5V

19 pin

+3.3V.S

SPS power supply 3.3V.S

21-25 pin

27 pin

RE_IO3

28 pin

+24V.S

SPS power supply 24V.S

29 pin

RE_102

30 PIN

RE_101